Earthwork is one of the most important elements in road construction because it establishes a stable foundation. That is why the road’s base layers are as important as the finished surface. First, the contractor builds embankments using cuts and fills.

What material is used for road construction?

Bituminous Materials Bituminous material, or bitumen in the form of asphalt, is one of the major highway construction materials used. Asphalt is normally a residue product from the distillation of crude oil and, as refined, is a heavy, viscous material that is semisolid at normal atmospheric temperatures

What are the stages of road construction?

Stages in Road Construction

Clearing and Excavation. The area on which the road is going to be built on must be cleared of all vegetation, which requires the removal of trees, shrubs and bushes.

How many types of road construction are there?

There are three major types of concrete road surfaces, JPCP, JRCP, and CRCP; the distinguishing feature between the three being the joint system that is used to help prevent cracks from forming. Concrete is more long-lasting than asphalt and significantly stronger as well, but is quite expensive to lay and maintain.

A road surface (English), or pavement (American), is the durable surface material laid down on an area intended to sustain vehicular or foot traffic, such as a road or walkway. In the past, gravel road surfaces, macadam, hoggin, cobblestone and granite setts were extensively used, but these have mostly been replaced by asphalt or concrete laid on a compacted base course. Today, permeable paving methods are beginning to be used for low-impact roadways and walkways.

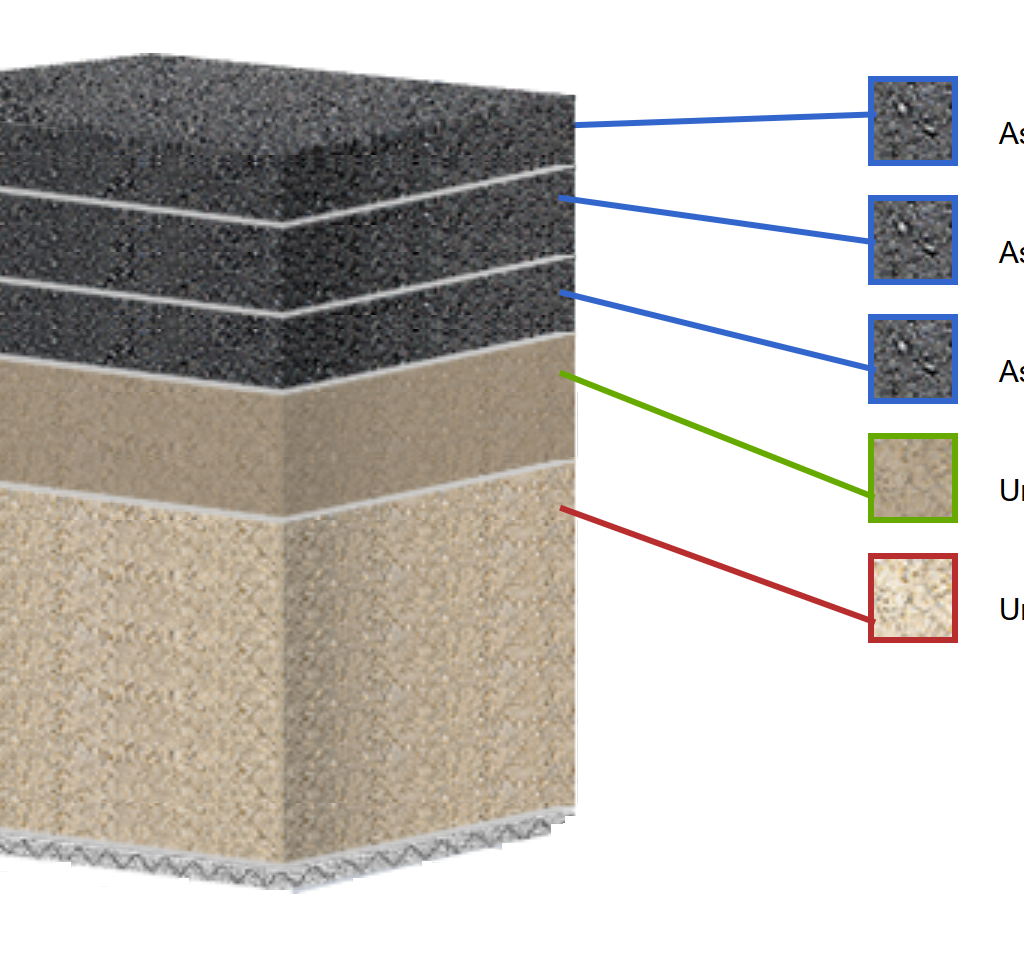

Asphalt (specifically, asphalt concrete), sometimes called flexible pavement since its viscosity causes minute deformations as it distributes loads, has been widely used since the 1920s. Most asphalt surfaces are laid on a gravel base, which is generally at least as thick as the asphalt layer, although some ‘full depth’ asphalt surfaces are laid directly on the native subgrade. In areas with very soft or expansive subgrades such as clay or peat, thick gravel bases or stabilization of the subgrade with Portland cement or lime may be required.

Closeup of asphalt on a driveway

Composite pavements combine a Portland cement concrete sublayer with an asphalt overlay. They are usually used to rehabilitate existing roadways rather than in new construction. Asphalt overlays are sometimes laid over distressed concrete to restore a smooth wearing surface.[28] A disadvantage of this method is that movement in the joints between the underlying concrete slabs, whether from thermal expansion and contraction, or from deflection of the concrete slabs from truck axle loads, usually causes reflective cracks in the asphalt.

An example of composite pavement: hot-mix asphalt overlaid onto Portland cement concrete pavement

Distressed pavement can be reused when rehabilitating a roadway. The existing pavement is broken up and may be ground on-site through a process called milling. This pavement is commonly referred to as reclaimed asphalt pavement (RAP). RAP can be transported to an asphalt plant, where it will be stockpiled for use in new pavement mixes

In-place recycling methods

Rubblizing of pavement: Existing concrete pavement is milled into gravel-sized particles. Any steel reinforcing is removed, and the ground pavement is compacted to form the base and/or sub-base layers for new asphalt pavement.[32] Ground pavement may also be compacted for use on gravel roads.[31]

Cold in-place recycling: Bituminous pavement is ground or milled into small particles. The asphalt millings are blended with asphalt emulsion, foamed bitumen, or soft bitumen to rejuvenate the aged asphalt binder.[31][33] New aggregate may also be added. The resulting asphalt mix is paved and compacted. It may serve as the top pavement layer, or it may be overlaid with new asphalt after curing.[34]

Hot in-place recycling: Bituminous pavement is heated to 120–150 °C (250–300 °F), milled, combined with a rejuvenating agent and/or virgin asphalt binder, and compacted. It may then be overlaid with new asphalt concrete.[34] This process typically recycles the top 50 mm (2 in) or less and may be used to correct surface defects, such as rutting or polishing.[34] To preserve the condition of the asphalt binder and avoid excessive hydrocarbon emissions, heating is typically achieved gradually through the use of infrared or hot air heaters.

Bituminous surface treatment (BST) or chipseal is used mainly on low-traffic roads, but also as a sealing coat to rejuvenate an asphalt concrete pavement. It generally consists of aggregate spread over a sprayed-on asphalt emulsion or cut-back asphalt cement. The aggregate is then embedded into the asphalt by rolling it, typically with a rubber-tired roller. This type of surface is described by a wide variety of regional terms including “chip seal”, “tar and chip”, “oil and stone”, “seal coat”, “sprayed seal”,[35] “surface dressing”,[36] “microsurfacing”[37] or as simply “bitumen.

Applying gravel, or “metalling”, has had two distinct usages in road surfacing. The term road metal refers to the broken stone or cinders used in the construction or repair of roads or railways,[ and is derived from the Latin metallum, which means both “mine” and “quarry”.The term originally referred to the process of creating a gravel roadway. The route of the roadway would first be dug down several feet and, depending on local conditions, French drains may or may not have been added. Next, large stones were placed and compacted, followed by successive layers of smaller stones, until the road surface was composed of small stones compacted into a hard, durable surface. “Road metal” later became the name of stone chippings mixed with tar to form the road-surfacing material tarmac

Pavement ends and turns into gravel surface road

Other surfaces

Pavers (or paviours), generally in the form of pre-cast concrete blocks, are often used for aesthetic purposes, or sometimes at port facilities that see long-duration pavement loading. Pavers are rarely used in areas that see high-speed vehicle traffic.

Brick, cobblestone, sett, wood plank, and wood block pavements such as Nicolson pavement, were once common in urban areas throughout the world, but fell out of fashion in most countries, due to the high cost of labor required to lay and maintain them, and are typically only kept for historical or aesthetic reason.

Markings

Main article: Road surface marking

Road surface markings are used on paved roadways to provide guidance and information to drivers and pedestrians. It can be in the form of mechanical markers such as cat’s eyes, botts’ dots and rumble strips, or non-mechanical markers such as paints, thermoplastic, plastic and epoxy.

See also

References

Nehme, Jean (14 July 2017). “About Long-Term Pavement Performance”. Federal Highway Administration. Retrieved 22 October 2017.

Raab, Robert (n.d.). “Long-Term Pavement Performance Studies”. Transportation Research Board. Retrieved 22 October 2017.

Deon Moyoweshumba. “the Importance of Tar Paving”. Gv TAR Construction Blog. 2022